R&D

The Best Professional Company in the Coating Field, Hankook Coatings

Characteristics by Coating

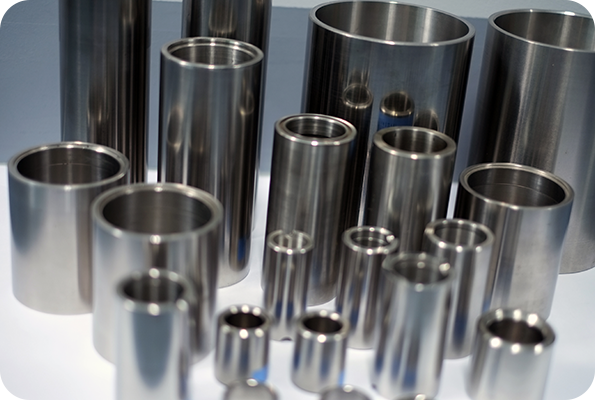

Hankook Coatings possesses the best technologyin the coating field.

Wear resistance and corrosion

resistance are basic!

Metal coating with various

characteristics

resistance are basic!

Metal coating with various

characteristics

Metal coating is a special alloy that has a wide range of uses. You can check

which coating is used in which environment by checking the information below.

which coating is used in which environment by checking the information below.

Properties : Wear resistance, corrosion resistance, electric heat,

Properties : Wear resistance, corrosion resistance, electric heat, and sliding

Types and Characteristics

| No | Type | Characteristics |

|---|---|---|

| 1 | Fe base | As an iron-based alloy, it contains various elements such as Cr and Ni depending on the application, is iron-based, and has the advantage of a relatively inexpensive metal coating. In addition, depending on the mix, amorphous glass metallization is possible, resulting in unique properties. |

| 2 | Aluminum base | Aluminum-based metal coating is resistant to corrosion and is used for places with corrosive atmosphere or moisture.

In particular, it is widely used in industries related to seawater, such as plants and ships. |

| 3 | Cobalt base | When used with Ni, Cr, etc., it becomes very resistant to high-temperature sulfur corrosion. Depending on the combination

with other elements, it can have a very high melting point, so it can be used at high temperatures and is also used under the name STELLITE. |

| 4 | Nikel base | Nickel-based alloys are mainly used in extreme high-temperature environments because they are highly resistant to

oxidation in high-temperature and high-pressure environments. |

| 5 | Titanium base | As titanium is light and has good corrosion resistance, it is widely used for artificial bones and implants.

It is also used in places where boric acid is widely used or in seawater atmospheres. |

| 6 | Molybdenum base | Molybdenum alloy is for places with high temperatures and is widely used in furnace atmospheres.

It is also widely used in high temperature friction atmospheres. |

| 7 | Copper base | Copper-based alloys have excellent heat conductivity and are used as coatings for electronic components such as

semiconductors. Additionally, when mixed with aluminum, it has the property robust to seawater corrosion. |

Cemented carbide coating

with high hardness and

corrosion resistance

with high hardness and

corrosion resistance

Cemented carbide is a carbide created when a material meets carbon, and it

shows very good performance when applied as a coating. In general, cemented

carbide coatings are known to have superior wear resistance compared to metal

coatings, and their corrosion resistance is far superior over metal coatings.

However, as cemented carbide has a lower thermal expansion coefficient and

higher brittleness than metal, separate processing (bonding) may be required.

shows very good performance when applied as a coating. In general, cemented

carbide coatings are known to have superior wear resistance compared to metal

coatings, and their corrosion resistance is far superior over metal coatings.

However, as cemented carbide has a lower thermal expansion coefficient and

higher brittleness than metal, separate processing (bonding) may be required.

Properties: Wearresistance and corrosionresistance

Properties: Wearresistance and corrosionresistanceTypes and Characteristics

| No | Type | Characteristics |

|---|---|---|

| 1 | Chromium Carbide | Chromium carbide basically has excellent corrosion resistance, and especially at high temperatures,

decarburization is less likely than tungsten carbide, so it has excellent wear resistance. It's also relatively inexpensive. |

| 2 | Tungsten Carbide | Tungsten carbide has excellent wear resistance and corrosion resistance at low temperatures and is the most widely used.

However, decarburization is relatively severe and hardness decreases significantly at high temperatures. |

Ceramic coating applied

in special environments

in special environments

Ceramic is an oxide formed when a substance meets oxygen. It has very high

hardness and excellent corrosion resistance, and has an insulating effect at high

temperatures. However, although it has high hardness, since it is very brittle and

breaks easily upon impact, and its coefficient of thermal expansion is low,

it has a risk of its falling off at high temperatures in some cases. Therefore, an

intermediate relief layer is often used. In this case, the construction cost may

rather increase.

hardness and excellent corrosion resistance, and has an insulating effect at high

temperatures. However, although it has high hardness, since it is very brittle and

breaks easily upon impact, and its coefficient of thermal expansion is low,

it has a risk of its falling off at high temperatures in some cases. Therefore, an

intermediate relief layer is often used. In this case, the construction cost may

rather increase.

Properties: Wear resistance, corrosion resistance, insulation,

and sliding

Properties: Wear resistance, corrosion resistance, insulation,

and slidingTypes and Characteristics

| No | Type | Characteristics |

|---|---|---|

| 1 | Aluminum Oxide | It is an oxide of a combination of aluminum and oxygen and its popular name is alumina. Basically, it is robust to wear and corrosion. It also has a low friction coefficient, thereby having sliding characteristics. |

| 2 | Chromium Oxide | Chromium oxide is particularly resistant to wear and tear, so it is used as a coating on mechanical parts used in extreme

environments and is also widely used for textile machinery. |

| 3 | Titanium Oxide | Titanium oxide has excellent dielectric properties and is often used for components such as semiconductors. |

| 4 | Zirconium Oxide | Zirconium oxide (zirconia) has all the characteristics of ceramics and is particularly robust to high temperatures.

Therefore, it is often used for heat shielding purpose, and is the most expensive coating. |